Before starting a landscape edging project, one of the first decisions you’ll face is whether to use pre-formed concrete curbing blocks or invest in the superior, seamless look of poured-in-place concrete curbing. As experts in concrete curbing equipment and techniques, Curb Depot explains why poured curbing is the clear choice for durability, aesthetics, and long-term value.

While blocks may seem like a simpler, initial option, they introduce a host of long-term problems that poured curbing, especially when installed with a high-quality machine like our Harpten, completely avoids.

The Case for Concrete Curbing Blocks

Concrete curbing blocks, or pavers, are individual units that are laid end-to-end to form a border.

| Advantage | Description |

|---|---|

| Initial Simplicity | They are easy to transport and can be installed without specialized machinery. |

| DIY Appeal | Homeowners can often install them quickly over a weekend. |

| Variety | Available in various shapes and colors from big-box stores. |

The Inherent Flaws of Block Curbing

Despite the initial appeal, blocks have significant drawbacks that compromise the integrity and appearance of your landscape border over time.

-

Weak Points and Instability

The fundamental flaw of block curbing is the seams. Every block connection is a weak point. Over time, natural freeze-thaw cycles, ground movement, and water erosion cause these blocks to shift, heave, and separate. This results in:- Weed Growth: Gaps between blocks become perfect breeding grounds for weeds and grass, defeating the purpose of a clean border.

- Uneven Lines: The straight, uniform line you started with quickly becomes wavy and disjointed, requiring constant maintenance to realign.

- Containment Failure: The shifting blocks fail to contain mulch, gravel, or soil effectively.

-

Lack of Durability

Blocks are often made with a lower-strength concrete mix than the zero-slump mix we use for poured curbing. They are susceptible to chipping and cracking, and because they are not anchored, they can be easily displaced by lawnmowers or heavy foot traffic.

The Unmatched Superiority of Poured-in-Place Curbing

Poured-in-place concrete curbing, created using a specialized machine, is a continuous, monolithic structure. This single, seamless piece of concrete is what makes it the professional standard and the superior choice.

-

Seamless, Monolithic Strength

When we install a curb with our equipment, we create a single, continuous piece of concrete. This eliminates all the weak points inherent in block curbing. The result is a border that is:- Incredibly Durable: It resists ground movement, heaving, and cracking far better than blocks.

- Weed-Proof: There are no seams for weeds to penetrate, keeping your landscape beds pristine.

- Permanent: A poured curb is a long-term investment that maintains its shape and integrity for decades.

-

Professional Aesthetics and Customization

Poured curbing offers a level of customization and finish that blocks simply cannot match.- Custom Profiles: With our Harpten machine, we can use various molds to create custom profiles—from elegant slant styles to practical mower edges—that perfectly suit the landscape design.

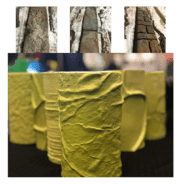

- Integrated Color and Texture: We can mix integral color directly into the concrete and apply professional textures using a concrete curbing stamp roller. This allows us to mimic the look of natural stone, brick, or slate with a seamless, high-end finish. For a closer look at the stunning textures possible, read our guide on Curbing Stamp Patterns: Complete Guide to Decorative Concrete Textures.

-

The Right Equipment Makes the Difference

The difference between a mediocre poured curb and a professional one lies in the equipment. Our Harpten Curbing Machine ensures the concrete is extruded with maximum compaction, which is critical for strength and durability.

| Feature | Concrete Curbing Blocks | Poured-in-Place Curbing (Curb Depot Method) |

|---|---|---|

| Structure | Individual, separate units | Monolithic, seamless structure |

| Durability | Prone to shifting, heaving, and separation | Extremely durable and stable |

| Weed Control | Poor; weeds grow in seams | Excellent; no seams for weeds |

| Aesthetics | Limited, segmented look | Custom profiles, seamless, high-end finish |

| Installation | Manual labor, simple tools | Requires a specialized curbing machine |

Take Your Curbing Projects to the Next Level

A DIY block project might seem cheaper at first, but once you factor in the upkeep, repairs, and replacement, it often ends up costing more. Poured curbing delivers better long-term value.

If you’re a homeowner, you can still achieve this professional look by following our How to Pour Concrete Curbing: A Complete DIY Guide, which details the process. If you’re a contractor, investing in our Curbing Packages and learning how to use a curbing machine will allow you to offer this superior product to your clients, setting you apart from the competition. For more information about the training and equipment we offer, contact us today.

Ready to Order Your New Curbing Trailer? Request More Info.

Give us a call at (920) 740-2218 or simply fill out the form below to learn more about getting all the tools and training to get started. We make the process easy to start earning money in landscape curbing.