When I quoted $2,400 for professional concrete curbing around my property, I nearly fell over. That’s when I discovered the world of DIY concrete curbing—and completed the same project for just $340. The secret? Understanding that professional-quality concrete curbing isn’t just about mixing cement and pouring it along your landscape. It’s about using the right equipment, proper techniques, and professional-grade materials that specialized equipment suppliers have made accessible to homeowners and contractors alike.

Why Concrete Curbing Matters

Concrete curbing isn’t just decorative—it’s functional landscaping that prevents grass invasion, defines planting areas, and creates clean property lines. When done correctly, it can last 20 years or more and significantly boost your property value. The key is approaching it like a professional would.

Essential Curbing Equipment and Materials

- Curbing Machine: While hand-forming is possible, a quality curbing machine ensures consistent height, width, and professional appearance.

- Ground Preparation Tools: You’ll need compactors, grading tools, and string lines to create a solid foundation that prevents cracking and settling.

- Concrete Mixers: Portable mixers ensure fresh concrete throughout your project, maintaining workability and strength.

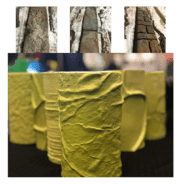

- Specialized Accessories: Stamps, vertical profiles, and other accessories transform basic curbing into landscape features.

The Professional Curbing Process

Here’s how professionals do concrete curbing that you can follow at home:

- Phase 1: Planning and Layout – Mark curbing paths with spray paint and use string lines for straight runs and smooth curves.

- Phase 2: Ground Preparation – Excavate trenches, compact soil, and add gravel base for stability and drainage.

- Phase 3: Concrete Mixing and Pouring – Use a 3,500-4,000 PSI mix, keeping consistency thick but workable.

- Phase 4: Forming and Shaping – Run curbing machines steadily; hand-form with professional-grade forms.

- Phase 5: Finishing Touches – Apply stamps, color, and sealers for decorative and lasting results.

Professional Tips for Success

- Timing: Work in mild weather (50-80°F) and avoid extremes.

- Quality Control: Test consistency often and adjust water gradually.

- Expansion Joints: Cut control joints every 8-10 feet.

- Curing: Keep concrete moist for 7 days with water spray and plastic covering.

Common Mistakes to Avoid

Don’t skip ground preparation—it accounts for 70% of your project’s success. Avoid over-watering concrete, working with concrete that’s setting, or stopping mid-section with machines.

Investment and Returns

A typical 200-foot curbing project costs $340–$500 in materials versus $1,600–$3,000 for professional installation. Quality equipment pays for itself in a single project.

Transform Your Property with Professional Results

Concrete curbing transforms ordinary landscapes into defined, professional-looking properties while providing decades of maintenance-free borders. The difference between amateur and professional results lies in using the right equipment, quality materials, and proven techniques.

Ready to create professional-quality concrete curbing that rivals contractor work? Curb Depot provides everything you need—from precision curbing machines and concrete mixers to professional stamps, coloring systems, and sealers. Our complete curbing packages include trailers, accessories, and expert guidance to ensure your success. Whether you’re an ambitious homeowner or expanding contractor, our equipment and consumables deliver the professional results you’re seeking.

Contact Curb Depot today and discover how professional-grade tools make professional-quality curbing achievable for everyone.

Ready to Order Your New Curbing Trailer? Request More Info.

Give us a call at (920) 740-2218 or simply fill out the form below to learn more about getting all the tools and training to get started. We make the process easy to start earning money in landscape curbing.