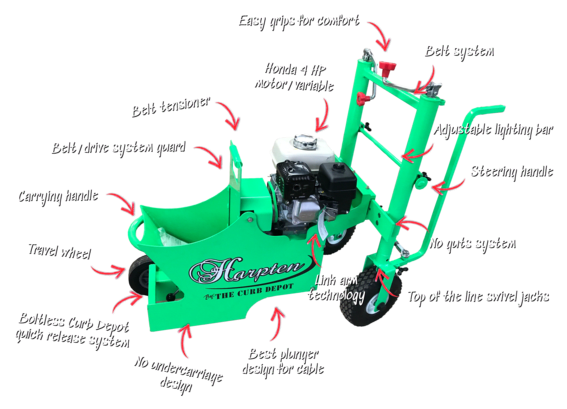

The All-New

Harpten Curbing Machine

Get the job done quicker and easier with the all-new Harpten Curbing Machine. With smoother feeding and less moving parts, it’s built to last without sacrificing any power.

The All-New

Harpten Curbing Machine

Get the job done quicker and easier with the all-new Harpten Curbing Machine. With smoother feeding and less moving parts, it’s built to last without sacrificing any power.

The Harpten Has Everything You Need To Get The Job Done.

- Easy grips for comfort

- Belt system

- Adjustable lighting bar

- Steering handle

- No guts system

- Top of the line swivel jacks

- Link arm technology

- Best plunger design for cable

- No undercarriage design

- Boltless Curb Depot quick release system

- Travel wheel

- Carrying handle

- Belt/drive system guard

- Belt tensioner

- Honda 4 HOP motor/variable

No-guts system.

Fewer Breakdowns & Repairs

The Harpten is the only curbing machine on the market with 0 moving parts down by the plunger. This means less service and maintenance for your machine’s bearings, auger, track & trolley. Enjoy a longer life from your machine with less headache.

Set your curb’s foundation.

Smoother Cable Feed

The Harpten’s design feeds cable smoother into your curb. Less wavy cable creates fewer weak points and means a better product with less call-backs from your clients.

No voids. No hopping.

Tighter Compaction

The 190lb. Harpten is heavy enough to create beautiful curb without voids or hopping, but light enough to work with day-in and day-out. Our plunger design has a 1″ inch lift, that creates tighter compaction.

Proudly manufactured domestically.

Widest Wheel Base, Better Stability

With a wider wheelbase than traditional curbing machines (24″ vs 14″), the Harpten offers better stability when maneuvering. The wider base plate also allows you to extrude concrete closer to the wheel, allowing you to work in tighter spaces like next to flower beds or fence lines.

Tighten your belt as you go.

Belt Tensioner

Have complete control of your belt’s tension as you lay curb so that you can maintain the tight compaction regardless of the ground condition or the angle of the turns you’re making.

Less time, less labor, more money in your pocket.

Less Troweling

Get a smooth, compact curb with less work and time spent troweling. This allows you to focus on other aspects of the job and get better, more detailed outcomes for your clients.

Bolt-free Mold System

Replace your molds in only 10 seconds, instead of 5 minutes.

- Molds pop in and out with ease

- No bolts to undue

- Easier to clean your machine after every job

- Save time changing molds on the job

- No slipform needed

Brackets on Both Sides

Choose to run your extruder clockwise or counterclockwise.

Easily reverse the direction of your molds and switch your handle to either side. This feature is great if your curbing project ends at a fence or wall.

Honda Motor

Powerful – 74 HP Honda 6x 120 ECO TEC Engine

Made in the USA

Proudly manufactured domestically.

Ready to order your own Harpten? Request More Info.

Give us a call at (920) 740-2218 or simply fill out the form below to learn more about getting your hands on the all-new Harpten Curbing Machine.