The true mark of a professional curbing contractor is the ability to handle complex designs, especially tight curves, intricate S-shapes, and sharp transitions. While laying a straight curb is straightforward with a quality machine, mastering the art of the curve requires precision, technique, and the right equipment. Curb Depot designs its machinery and training programs to ensure you can execute these challenging designs flawlessly, turning complex projects into high-margin opportunities.

This guide focuses on the specialized techniques and equipment adjustments needed to achieve smooth, professional results on nonlinear curbing paths.

Phase 1: Precision Layout for Complex Paths

Unlike straight runs, where a simple string line suffices, curves require a more nuanced approach.

1. The Importance of the Radius

For smooth curves, we recommend establishing a consistent radius. Use a flexible hose or a series of small stakes to define the arc. The tighter the curve, the more critical it is to use a machine designed for maneuverability.

Our Harpten Curbing Machine is designed to handle tighter curves than standard curbing machines, enabling smooth navigation.

2. Marking the Transition Points

Clearly mark where a straight run transitions into a curve, and where a curve transitions into a reverse curve (an S-shape). These transition points are where the operator must be most attentive while guiding the machine and maintaining a steady pace.

Phase 2: Machine Operation on Curves

The extrusion process on a curve differs significantly from that of a straight line. The operator must manage the machine’s forward motion while steering the mold to follow the marked path.

1. Slow and Steady Pace

On curves, speed is the enemy of quality. We instruct our trainees to slow the machine’s pace by 25% to 50% compared to a straight run. This slower speed allows the concrete to be compacted more effectively around the curve and gives the operator time to make minute steering adjustments.

2. Guiding, Not Forcing

The machine should be guided gently along the curve. Forcing the machine will result in a distorted profile and uneven compaction. The auger system in our equipment is designed to push concrete through the mold evenly, even as the machine turns.

3. Continuous Concrete Feed

Maintaining a continuous, consistent feed of the zero-slump concrete mix is even more critical on curves. Any interruption can create a visible seam or a weak point that is difficult to repair without tearing out a section.

Phase 3: Specialized Techniques for Tight Corners and S-Curves

1. Handling Tight Radii

For very tight curves (small radius), the outside edge of the curb will travel a greater distance than the inside edge. This can cause the concrete to tear or the profile to deform. The solution uses a technique called “feathering,” in which a specialized trowel is used to smooth and compact the concrete along the outside edge immediately after extrusion.

2. S-Curves and Reverse Transitions

S-curves require a smooth transition from a curve in one direction to a curve in the opposite direction. The key here is the layout. The transition point must be perfectly level, and the operator must execute a seamless steering reversal. This is a skill best learned through hands-on practice, which is why we emphasize it in our comprehensive training programs.

Phase 4: Finishing Complex Designs

Decorative finishes on curves require a slightly different approach than on straight runs.

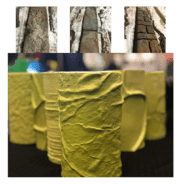

1. Stamping on Curves

Using a curbing stamp roller, apply the pattern carefully to avoid distortion. We recommend using a flexible stamp or a smaller roller designed for curves. The operator must ensure the pattern’s grout lines remain perpendicular to the curb’s edge, even as the curb bends.

2. Detailing and Sealing

After stamping, the detailing process—such as carving out grout lines or adding texture—is often more intensive on curves to ensure the pattern looks natural. Once the curb is fully cured, a high-quality sealer is applied to protect its complex texture and color, ensuring its aesthetic appeal endures.

Master Complex Curbing With Curb Depot

Mastering complex curbing sets amateur installers apart from professional contractors who command premium pricing. By investing in our high-quality curbing equipment and proven installation techniques, you can confidently tackle any project, no matter how intricate the design demands.

We offer a range of Curbing Packages that include the Harpten machine and the necessary molds and tools for handling simple and complex installations. Our training programs ensure you understand the advanced techniques required for radius curbing, tight curves, and challenging site conditions.

Contact Curb Depot today to discuss equipment packages, training options, and how our expertise can help you master even the most demanding landscape curbing installations.

Ready to Order Your New Curbing Trailer? Request More Info.

Give us a call at (920) 740-2218 or simply fill out the form below to learn more about getting all the tools and training to get started. We make the process easy to start earning money in landscape curbing.