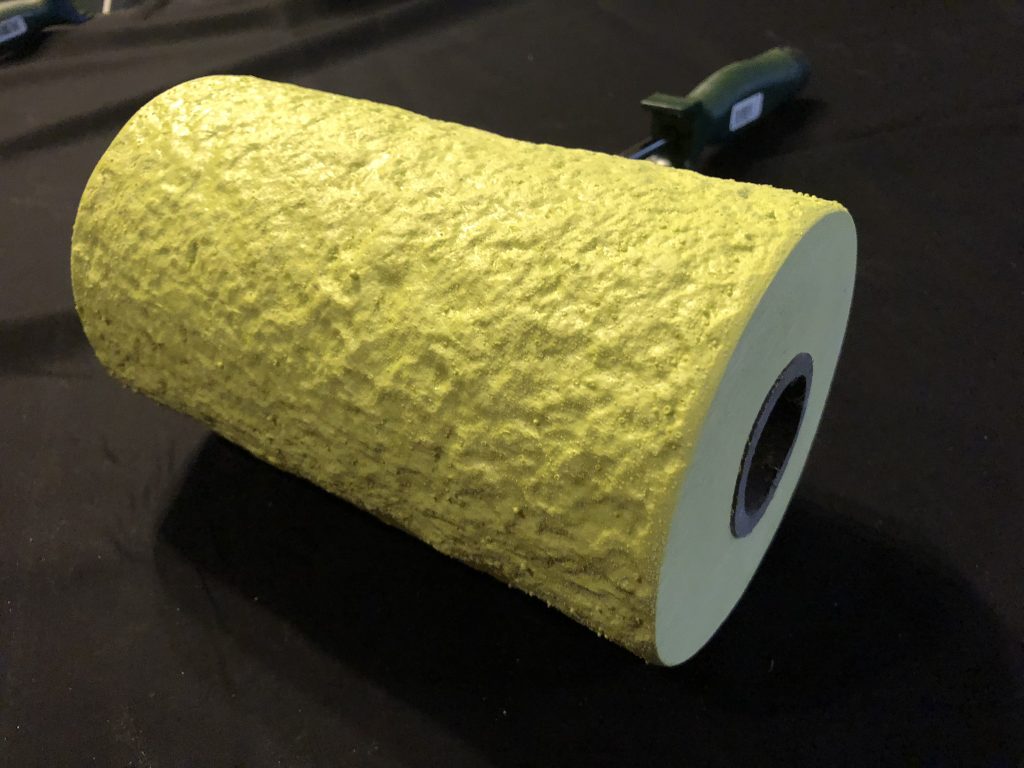

In the world of landscape curbing, functionality is only half the story. The other half is the aesthetic appeal that transforms a simple border into a stunning design element. We know that the difference between a good job and a great job often comes down to the texture. That is where the concrete curbing stamp roller becomes an indispensable tool for any professional curber.

These stamping rollers are the secret weapon for achieving realistic, high-end finishes that mimic natural stone, brick, or slate, all while maintaining the durability and seamless integrity of poured concrete.

Why Stamp Rollers are Superior to Hand Stamps

While hand stamps work for small, intricate areas, the stamp roller is the professional’s choice for continuous curbing applications. Key advantages include:

- Speed and Efficiency: Stamp rollers enable fast, continuous application compared to hand stamps that require constant repositioning.

- Seamless Consistency: Deliver uniform texture along the entire curb without pattern misalignment or visible seams.

- Ergonomic Design: Long handles allow you to use them while standing, eliminating the bending and repetitive motion required with hand stamps.

- Uniform Texture Depth: Even rolling pressure creates consistent depth and detail, unlike the variable pressure of manual stamping.

Our stamp rollers apply patterns with perfect pressure and release, ensuring intricate details transfer cleanly onto fresh concrete curbing.

Choosing the Right Texture for the Job

The variety of stamping textures available allows us to cater to any landscape style, from rustic to modern. The key is selecting a pattern that complements the surrounding hardscape and architecture.

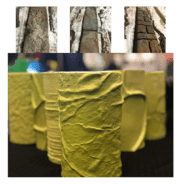

Natural Stone Textures

These are our most popular options, designed to replicate the look of quarried stone. Patterns like Fractured Limestone and Pacific Basalt are applied to create deep, realistic grout lines and stone faces. This high-end look is a major selling point for clients seeking a premium finish in their landscape design.

Brick and Paver Patterns

For properties with existing brickwork or paver patios, a brick-style stamp roller provides a seamless transition. The roller ensures the pattern is straight and uniform, avoiding the unevenness that can plague individual brick paver installations.

Wood Grain and Unique Finishes

We also offer specialized stamp rollers that create unique textures, such as weathered wood grain. These are perfect for garden beds or areas where a softer, more organic look is desired.

Integrating the Stamp Roller into Your Workflow

The stamp roller is used during the finishing stage of the curbing process, immediately after the curb has been extruded and initially troweled.

Step 1: Extrusion and Initial Troweling

First, the concrete must be extruded using a quality machine like our Harpten Curbing Machine. Once extruded, a quick pass with a finishing trowel smooths the surface and prepares it for stamping. Initial troweling removes imperfections and ensures the concrete has reached the ideal consistency—firm enough to hold detail but still workable.

Step 2: Applying the Release Agent

Before rolling, a liquid or powdered release agent must be applied to the concrete surface and the roller itself. This is a crucial step that prevents the concrete from sticking to the roller, ensuring a clean release and preserving the texture’s detail. It also often imparts a secondary color, adding depth and realism to the final decorative concrete.

Many installers lightly mist the curb with a liquid release and dust a powdered release over high-detail areas. The combination helps the roller glide cleanly and creates deeper color variation in the final finish.

Step 3: The Rolling Technique

The technique is simple: place the stamp roller at the start of the curb and apply firm, even pressure as you roll it along the length. The goal is a single, continuous pass. Overlapping or re-rolling can distort the pattern. The long handle of our rollers allows you to maintain a comfortable, upright posture while guiding the tool.

Final Touches: Color and Sealing

Once the texture is applied, the final steps help maximize the visual impact and longevity of concrete curbing.

- Coloring: Whether you use integral color mixed into the concrete or a topical stain, choosing the right color is essential. For inspiration, check out our guide on Concrete Curbing Colors: 15 Beautiful Options for Your Landscape Design.

- Sealing: A high-quality sealer protects the textured surface, locks in the color, and makes the curb easier to clean and maintain over time.

Explore Our Professional Stamping Tools

Curb Depot not only supplies the best stamp rollers but also a wide range of stamps and accessories you need to deliver a truly professional, textured finish that will delight your clients and elevate your curbing business. Browse through our curbing equipment, accessories, and other supplies today.

Ready to Order Your New Curbing Trailer? Request More Info.

Give us a call at (920) 740-2218 or simply fill out the form below to learn more about getting all the tools and training to get started. We make the process easy to start earning money in landscape curbing.