DIY concrete curbing gives homeowners a hands-on way to create beautiful landscape edging while significantly reducing project costs. While professional landscape curbing provides unmatched convenience and consistency, many property owners prefer the satisfaction and savings of a do-it-yourself approach.

If you’re handy and willing to invest the time, a DIY curbing project can cut total costs by approximately half compared to hiring contractors. At Curb Depot, we believe in empowering homeowners and aspiring entrepreneurs with the knowledge needed for successful concrete curbing installations.

The Cost-Saving Advantage of DIY Curbing

Manual labor is the largest expense in professional curbing installations. Eliminating this cost creates substantial savings for motivated homeowners.

Professional landscape curbing typically ranges from $8 to $18 per linear foot, depending on regional pricing, design complexity, and contractor expertise. DIY concrete curbing projects often reduce costs to approximately $3 to $6 per linear foot by doing away with labor expenses and focusing on material costs alone.

- Professional Installation: $8-$18 per linear foot (includes labor, materials, equipment)

- DIY Project: $3-$6 per linear foot (materials only, your time investment)

- Potential Savings: 50%-60% reduction in total project cost

- Labor Component: Eliminated entirely with a DIY approach

These savings make DIY curbing an attractive option for homeowners willing to invest time instead of cash while still achieving improved curb appeal and higher property values.

Planning Your DIY Concrete Curbing Project

Any successful DIY concrete curbing project begins with thorough planning to maximize efficiency and minimize material waste.

Calculate your project perimeter precisely, as over-ordering concrete increases costs while under-ordering creates delays and inconsistent seams. Plan your concrete curbing layout to minimize complex curves and connections that require advanced techniques.

Choosing the right tools helps keep your DIY curbing costs under control. Manual curbing molds work well for residential projects and cost significantly less than commercial equipment. Rent concrete mixers for larger projects rather than purchasing bags of pre-mixed concrete or attempting to mix concrete yourself. Essential tools include quality trowels, floats, and basic hand tools for shaping and finishing.

Consider your timeline carefully, as DIY concrete curbing requires long hours of work. Because weather plays a major role in proper curing, install concrete curbing on a mild, dry day—ideally 50°F to 80°F, with no rain or strong winds expected.

Mastering DIY Concrete Mix and Installation

Material costs are the biggest part of a DIY curbing project, so getting your concrete mix right is essential—not just for a strong curb, but for keeping your budget on track.

Low-slump concrete mixes retain their shape when removed from molds, which is essential for successful concrete curbing installations. A common starting ratio uses 1:2:3 proportions (cement: sand: aggregate) with minimal water. Adjust moisture levels based on local conditions and chosen materials, as proper consistency affects your curbing’s workability and final strength.

The DIY installation process involves manual concrete placement and finishing techniques. Press the concrete firmly into the manual molds, ensuring they’re filled completely with no air pockets. Lift the molds carefully to maintain a clean profile and consistent dimensions. This method requires more time than machine installation, but eliminates the expense of getting specialized equipment.

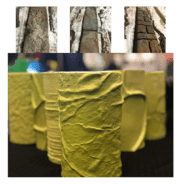

Adding decorative finishes boosts curb appeal without adding much to your cost. Affordable stamping tools and texture rollers create stone-like appearances that rival professional installations. Apply finishes while the concrete is workable, typically within 15 to 30 minutes of placement, depending on weather conditions.

For a more thorough installation overview, read Landscape Curbing Process: From Planning to Installation in 7 Steps.

When To Consider Professional Equipment

DIY concrete curbing is suitable for single residential projects, but successful installations often generate interest from neighbors and friends seeking similar improvements.

If you have an aptitude for curbing work or receive requests for additional projects, investing in professional-grade equipment can turn hobby-level skills into income opportunities. The labor savings achieved through DIY methods can fund equipment purchases that enable contractor-level capabilities.

Curb Depot offers comprehensive curbing packages for homeowners transitioning into the industry. Professional machines like the Harpten increase installation speed, improve consistency, and create earning potential that transforms cost savings into revenue generation. Our training programs provide the technical knowledge needed to operate equipment safely and effectively.

Start Your DIY Curbing Project Today

DIY concrete curbing is an excellent opportunity to enhance your property’s landscape design while developing valuable construction skills. With careful planning, the right materials, and attention to detail, homeowners can achieve professional-looking results while saving a lot of money.

Ready to tackle your curbing project or explore equipment options for future business opportunities? Contact Curb Depot today to discuss materials, tools, and training programs that support successful concrete curbing installations at any skill level.

Ready to Order Your New Curbing Trailer? Request More Info.

Give us a call at (920) 740-2218 or simply fill out the form below to learn more about getting all the tools and training to get started. We make the process easy to start earning money in landscape curbing.