While Curb Depot is renowned for revolutionizing landscape curbing, we also bring the same skill and precision to vertical concrete stamping. This advanced technique turns plain walls—like retaining walls, foundation walls, outdoor kitchens, and fireplace surrounds—into beautiful, lifelike stone, rock, or brick features.

This technique is a game-changer for professional contractors, offering a high-margin service that dramatically enhances a property’s aesthetic appeal. Curb Depot provides specialized tools to help you explore this art form and deliver breathtaking results.

What Is Vertical Concrete Stamping?

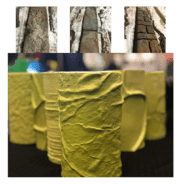

Unlike traditional horizontal stamping, which uses the weight of the concrete to hold the pattern, vertical stamping involves applying a specialized, lightweight concrete mix (often referred to as a “vertical overlay”) to a wall surface. While the overlay is still pliable, large, flexible mats or vertical concrete stamps are pressed into the material to create deep, three-dimensional textures.

The result is a surface that is virtually indistinguishable from natural stone, but with the superior durability and cost-effectiveness of concrete.

Tools and Techniques That Make Vertical Stamping Work

Mastering vertical stamping requires specialized materials and tools that differ from those used in curbing.

1. The Right Overlay Mix

The key to success is the mix. The vertical overlay must be sticky enough to adhere to the wall without sagging, yet workable enough to accept the deep texture of the stamps. We recommend a polymer-modified cementitious mix that offers:

- Excellent Adhesion: It bonds securely to existing concrete, masonry, or even drywall.

- Lightweight Composition: Reduces the load on the wall structure.

- Extended Working Time: Allows the artisan time to apply, texture, and detail the surface.

2. Specialized Vertical Stamps

Our vertical stamps are larger and more flexible than curbing rollers, designed to replicate the organic, irregular shapes of natural rock faces, such as slate, granite, or mountain stone. These stamps are essential for achieving the deep relief and authentic look that clients demand.

Step-by-Step Guide to Vertical Stamping

1. Surface Preparation

The wall must be clean, structurally sound, and properly prepped. This involves power washing, repairing any cracks, and applying a bonding agent to ensure maximum adhesion of the overlay.

2. Applying the Overlay

The overlay is typically troweled or sprayed onto the wall in a layer between 1/2 inch (residential applications) and 1 inch thick (plus reinforcement for commercial applications). This is the most physically demanding step, requiring a smooth, consistent application to ensure uniform thickness for stamping.

3. Texturing with Vertical Stamps

Once the overlay has reached the right consistency (often called the “plastic state”), the stamps are pressed firmly into the material.

- Overlap is Key: Unlike curbing, where a seamless roll is desired, vertical stamps are often overlapped slightly to create a natural, non-repeating pattern, mimicking a real stone wall.

- Detailing: After the main texture is applied, specialized detailing tools—such as chisels, grout line tools, and texture skins—are used to enhance the realism, carve out deep grout lines, and create natural imperfections.

- Pro Tip: To achieve a natural, authentic stone look, slightly rotate, offset, or stagger each stamp during overlap. This prevents repetitive or artificial patterns from appearing across the wall. Experienced contractors often vary pressure subtly as well, emphasizing high and low points in the texture. These small adjustments dramatically enhance the realism, making vertical concrete appear indistinguishable from real quarried stone.

4. Coloring and Sealing

This is where the artistry truly comes to life. Coloring is typically done with acid stains or water-based stains applied in multiple layers to create depth and variation.

- Base Color: A base color is applied to the entire surface.

- Accent Colors: Secondary colors are brushed or sponged into the recesses and high points to mimic the natural mineral deposits and weathering of real stone.

- Sealing: A high-quality sealer is applied to protect the finish, enhance the color, and make the wall resistant to moisture and UV damage.

Expand Your Services With Vertical Concrete Stamping

Vertical stamping is a natural complement to our core curbing business. If you already offer decorative concrete curbing installation, adding vertical stamping to your service menu is a logical and profitable next step.

This technique is particularly effective when paired with landscape curbing, allowing you to create a cohesive, high-end look across the entire property. Imagine a stamped concrete curb that perfectly matches the texture and color of a newly stamped retaining wall—that’s the level of professionalism we help you achieve.

Curb Depot supplies stamps and consumables to get you started. By mastering this technique, you’re not just stamping concrete; you’re creating lasting, beautiful works of art that set your business apart.

Ready to Order Your New Curbing Trailer? Request More Info.

Give us a call at (920) 740-2218 or simply fill out the form below to learn more about getting all the tools and training to get started. We make the process easy to start earning money in landscape curbing.