Many contractors wonder if a road paver can double as a solution for residential concrete projects. While road pavers excel at large-scale paving, their application for residential edging is limited. This guide explains the differences between road pavers and curb extruders—and why the right choice can save time, money, and frustration.

Curb Depot helps contractors choose the right machine for each project. Whether it’s a road paver for larger placements or a curb extruder for precise residential edging, we provide the guidance and equipment to maximize efficiency and results.

Understanding Road Pavers vs Curb Extruders

The fundamental differences between these machines go beyond their names and directly impact their effectiveness in residential applications.

What Is a Road Paver?

A road paver is designed primarily for large-scale asphalt paving and concrete placement on roadways, parking lots, and other broad surfaces. These machines excel at laying continuous strips of material across wide areas, with consistent thickness and a smooth finish. Road pavers typically handle higher volumes of material and are built for efficiency on expansive projects where speed and coverage matter most.

What Is a Curb Extruder?

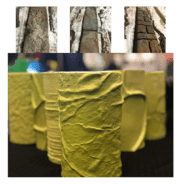

A curb extruder, also known as a concrete curb machine, produces precise, continuous concrete profiles for landscape edging and decorative applications. These machines are engineered for accuracy, allowing operators to form consistent curb profiles with clean lines and professional finishes. Curb extruders work best with specialized concrete mixes designed for vertical extrusion and detailed shaping.

Key Functional Differences

- Application: Road pavers handle broad surface coverage; curb extruders create narrow, precise profiles.

- Material handling: Road pavers work with various paving materials; curb extruders use specialized concrete curbing mixes.

- Project scale: Road pavers suit large commercial jobs; curb extruders excel in residential landscape curbing.

- Precision: Curb extruders offer superior control for detailed decorative concrete work.

Which Equipment Works Best for Residential Edging Projects?

Residential concrete edging requires specialized approaches, making equipment selection a critical factor in delivering consistent, professional results.

When To Use a Curb Extruder for Residential Work

Curb extruders are the clear choice for most residential landscape edging projects. These machines excel when you’re creating decorative borders around flower beds, driveways, and walkways. The precision they deliver enables contractors to produce tight turns and consistent shapes that homeowners expect in decorative curbing.

For contractors focusing on residential concrete curbing, a dedicated curb machine is versatile enough to accommodate a wide range of property layouts and design requirements.

Road Paver Applications in Residential Settings

Road pavers can be valuable for residential contractors handling broader projects that include driveways, patios, or extensive concrete paving work. If your services include landscape curbing and larger concrete placement projects, a road paver might serve dual purposes. However, these machines typically require larger crews and aren’t cost-effective for small-scale residential edging jobs.

Cost and Efficiency Considerations

Curb extruders generally offer a better return on investment for residential specialists due to their lower operating costs and reduced labor requirements. In cold climates like Wisconsin, which require cold-weather curbing techniques, the precision of a curb extruder helps achieve consistent results even under challenging conditions.

Making the Right Choice for Your Business

Beyond the technical specifications, your decision on which equipment to use should align with your long-term business strategy and the demands of your target market.

Evaluate Your Project and Market Size

Consider your market size and typical project scope. If you’re primarily serving residential clients with landscape curbing needs, a specialized curb extruder will deliver better results and higher customer satisfaction. The learning curve for concrete curbing techniques is also more manageable with purpose-built equipment.

Consider the Local Climate and Market Opportunities

Think about your geographic service area and seasonal factors. In regions with shorter construction seasons, the efficiency and versatility of your chosen paving equipment help maximize productivity. Your equipment should address local climate challenges and market opportunities in the growing landscape curbing industry.

Assess Your Equipment Handling Knowledge

Assess your team’s experience with curbing equipment and specialized techniques. The curbing business requires specific skills for concrete mix design, machine operation, and finishing work that differ significantly from general concrete construction practices. Consider your current expertise level when choosing between equipment types.

Get Expert Guidance on Curbing Equipment

For residential edging projects, curb extruders are the clear winner over road pavers due to their precision, efficiency, and purpose-built design for landscape curbing. However, selecting the best curb extruder is just the first step in building a successful curbing business.

Having proper support and training makes all the difference. Let Curb Depot be your partner in this journey. Contact us to discuss your curbing equipment needs and discover how our expertise can accelerate your success in the landscape curbing industry.

Ready to Order Your New Curbing Trailer? Request More Info.

Give us a call at (920) 740-2218 or simply fill out the form below to learn more about getting all the tools and training to get started. We make the process easy to start earning money in landscape curbing.