Concrete curbing, a hardscape service forming permanent landscape edges, presents a viable small business opportunity in 2025 with the right operational and pricing model. This guide explores what concrete curbing entails, the rising demand for decorative and functional edging, and how per-foot pricing, material costs, and equipment choices drive profitability. It provides a profitability snapshot, market trends, a startup checklist, and equipment comparisons to help entrepreneurs launch or expand a concrete curbing service.

Make Money with Concrete Curbing: Your Profit Potential in 2025

Profitability in concrete curbing hinges on per-foot pricing, finish premiums, crew efficiency, and overhead control. Contractors often achieve higher margins by offering decorative finishes that command premium rates. Understanding these pricing bands and cost drivers is crucial for projecting job-level ROI.

Common curbing types, contractor price ranges, and typical material costs:

- Colored decorative curb: $3–$6 per ft (material $0.5–$1.50 per ft)

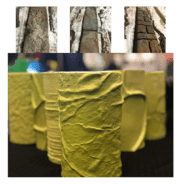

- Stamped decorative curb: $4–$7 per ft (material $1.00–$2.00 per ft)

- Functional plain curb: $2–$4 per ft (material $0.40–$1.00 per ft)

Decorative options like colored and stamped concrete curbing typically yield higher gross margins when labor and overhead are managed effectively.

How You’ll Make Money: Revenue and Pricing Strategies

Revenue streams include per-linear-foot installations, fixed-price project bids, and add-on decorative services such as stamping, coloring, sealants, and repair work. Pricing often varies by curb type and finish, allowing for a broader market reach. Concrete curbing also enables cross-selling with landscaping and hardscape services, increasing customer lifetime value.

What Impacts Your Profit?

Costs encompass materials (cement, pigments), labor, equipment amortization, transport, and overhead. Variable costs like materials and labor directly impact margins; optimizing bulk purchasing and crew productivity are key. Tracking labor hours per linear foot and equipment depreciation per job provides clear gross margin calculations for competitive pricing.

Real-World Examples: What Your Investment Could Return

A 200 ft residential colored curbing job at $4/ft could generate $800 revenue with approximately $300 in material and direct labor costs, yielding a gross profit near $500 before overhead. A single extrusion machine can facilitate multiple such jobs monthly, covering equipment financing. Increasing throughput or offering decorative upgrades shortens the payback period for equipment investments.

Why Concrete Curbing is Hot: Market Trends and What’s Driving Demand

Demand for concrete curbing is growing as homeowners and commercial clients seek durable, low-maintenance edging and decorative hardscape enhancements. This benefits from trends in outdoor living upgrades and increased landscaping spend.

Main trend drivers shaping the 2025 opportunity:

- Increased homeowner spending on outdoor upgrades drives decorative curbing demand.

- Commercial properties require durable delineation, supporting larger project bids.

- Equipment advances make scalable service delivery more feasible for small operators.

Demand from Homes and Businesses is Growing

Residential demand is fueled by curb appeal and home-improvement budgets, favoring decorative finishes. Commercial demand prioritizes durability and compliance for site perimeters and drainage, often leading to larger, repeatable contracts. Regional variations influence which segment dominates, impacting pricing and sales channels.

Ready to Launch? Starting Your Own Concrete Curbing Business

A successful curbing business launch requires a focused plan, clear legal and insurance posture, and practical funding and training. Early emphasis on quality, local marketing, and targeted sales accelerates revenue.

Practical startup checklist:

- Conduct local market research and define target segments and pricing bands.

- Create financial projections, including equipment amortization and crew labor rates.

- Build an operational plan for crew composition, equipment needs, and scheduling.

Your Blueprint for Success: Craft a Business Plan

A concise business plan should cover market sizing, pricing strategy, staffing, equipment, projected cash flows, and marketing. Define unit economics and include contingency planning for seasonal variability. Regularly refine projections with real job data.

Stay Legal and Protected: Permits, Insurance, and Contracts

Essential requirements include business registration, local permits, and zoning compliance. General liability, commercial auto, and workers’ compensation insurance are crucial. Clear contracts and warranties reduce disputes. Consulting local advisors helps align coverage with risk profiles. Contact Curb Depot for more information.

Your Toolkit for Success: Essential Concrete Curbing Equipment

Core equipment includes a curbing machine (extrusion or slip-form), a concrete mixer, finishing tools, transport, and site-prep tools. Matching machine capacity to demand prevents over- or under-investment, while maintenance and training are recurring cost considerations.

Equipment comparison by type, cost, and application:

- Extrusion machine: Low–Medium cost; ideal for 2–3 persons, residential and medium jobs.

- Slip-form machine: Medium–High cost; ideal for 3–4 persons, high-throughput commercial jobs.

- Small hobby/commercial unit: Low cost; ideal for 1–2 persons, low-volume decorative work.

Other Tools for a Perfect Curbing Finish

Supporting tools include concrete mixers, plate compactors for base consolidation, sod cutters, finishing trowels, stamping kits, and sealing equipment. Each tool plays a specific role in ensuring workability, base stability, and surface quality. Investing in durable tools and maintenance reduces downtime and warranty work.

Common Curbing Challenges and Smart Solutions

Curbing businesses face competition, weather-related durability issues, and customer expectation management. These can be mitigated through differentiation, technical practices, and clear communication.

Practical mitigation strategies:

- Differentiate by specializing in decorative finishes and offering bundled maintenance services.

- Mitigate climate risks with enhanced base prep, drainage solutions, and appropriate mix designs.

- Manage expectations with clear contracts, before/after photos, and defined warranty terms.

Ready to Shape Your Success?

With the right strategy, a concrete curbing business offers significant profit potential. Start planning your venture today to capitalize on growing market demand. For personalized advice and equipment inquiries, reach out to our experts at Curb Depot today.

Ready to Order Your New Curbing Trailer? Request More Info.

Give us a call at (920) 740-2218 or simply fill out the form below to learn more about getting all the tools and training to get started. We make the process easy to start earning money in landscape curbing.