Concrete curbing is an investment in a property’s aesthetic and functional appeal. While integral color provides a permanent, through-and-through hue, staining concrete curbing is a powerful alternative, especially for existing, uncolored curbs or for achieving unique, multi-toned, and translucent color effects that integral color cannot replicate. Staining is a professional technique that requires meticulous preparation and application to ensure a beautiful, long-lasting finish.

As concrete curbing specialists with decades of experience, Curb Depot explains how to stain concrete curbing so you can achieve professional-quality color results that enhance any landscape.

Staining vs. Integral Color: When to Choose Which

The decision to stain or use integral color depends on the project’s goals:

Integral Color: Best for New Curbs

Integral color is mixed into the concrete, making the color permanent and resistant to chipping or fading. It is the preferred method for new installations.

Staining: Best for Existing Curbs and Custom Effects

Staining is applied topically and is ideal for:

- Revitalizing Existing Curbs: Adding color to old, gray, or faded curbing

- Creating Depth: Using multiple colors or an antiquing effect to enhance stamped textures

- Achieving Translucency: Acid stains react chemically with the concrete, creating a mottled, marble-like finish that is unique and impossible to replicate with integral color

How To Stain Concrete Curbing in 4 Steps

Whether you’re refreshing old curbs or adding unique colors to new ones, a systematic approach to staining ensures a flawless, durable finish. Here’s how to do it in four essential steps.

Step 1: Meticulous Surface Preparation

The most critical step in the staining process is preparation. Any dirt, grease, or previous sealer will prevent the stain from penetrating the concrete, resulting in a patchy, short-lived finish.

- Cleaning and Degreasing: The curb must be thoroughly cleaned with a degreaser and a stiff brush, or with a pressure washer. All dirt, oil, and organic growth must be removed.

- Etching (If Necessary): For very smooth or dense concrete, a mild acid wash or etching solution may be required to open the concrete’s pores, allowing the stain to penetrate deeply. The surface must be completely neutralized and rinsed after etching.

- Ensuring a Dry Surface: The concrete must be completely dry before staining. Moisture will interfere with the chemical reaction of acid stains and dilute water-based stains.

Step 2: Choosing Your Stain Type

The two main types of concrete stains yield very different results and require different application processes.

- Acid-Based Stains: Acid stains contain metallic salts that react chemically with the concrete’s lime content. This reaction creates a permanent, translucent, and variegated color that cannot be peeled or chipped. Color options are limited to earth tones (browns, tans, soft greens, and blues).

- Water-Based Stains: Water-based stains are non-reactive and use fine pigment particles to color the concrete. They offer a much wider spectrum of colors, including vibrant blues, reds, and blacks. They are easier to apply and provide a more uniform, opaque color than acid stains.

Step 3: Professional Application Techniques

Proper application ensures even coverage and the desired aesthetic effect.

- Spray Application: The preferred method for acid and water-based stains is a pump sprayer. This allows for a fine, even mist that avoids pooling and streaking. For acid stains, a plastic sprayer prevents corrosion.

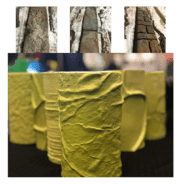

- Layering and Antiquing: For stamped curbing, professional installers often use a base color stain followed by a darker, diluted stain (an antiquing wash) to fill the recesses of the texture. This technique enhances the realism of patterns like cobblestone or textured slate.

- Neutralizing Acid Stains: After the acid stain has reacted (typically 4 to 8 hours), the residue must be neutralized with a baking soda and water solution, then thoroughly rinsed. Failure to neutralize will cause the stain to continue reacting and can damage the final sealer.

Step 4: Sealing for Protection and Enhancement

The final step is crucial for protecting the stained finish and bringing out the color’s full depth.

- Choosing the Right Sealer: A high-quality, UV-resistant concrete sealer must be applied. The sealer protects the stain from abrasion, moisture, and fading. Acrylic sealers are common, but polyurethane sealers offer superior durability.

- Enhancing the Color: A wet-look sealer will deepen the color and provide a glossy finish, while a matte sealer will offer a more natural, subtle appearance.

Finish Every Project Like a Pro With Curb Depot

Achieving a professional, durable stained finish requires not only the right technique but also the best products. Curb Depot supplies the professional-grade stains, sealers, and ground preparation tools you need to ensure your curbing projects are finished to the highest standard. To explore our full range of decorative concrete finishing products, contact Curb Depot today.

Ready to Order Your New Curbing Trailer? Request More Info.

Give us a call at (920) 740-2218 or simply fill out the form below to learn more about getting all the tools and training to get started. We make the process easy to start earning money in landscape curbing.